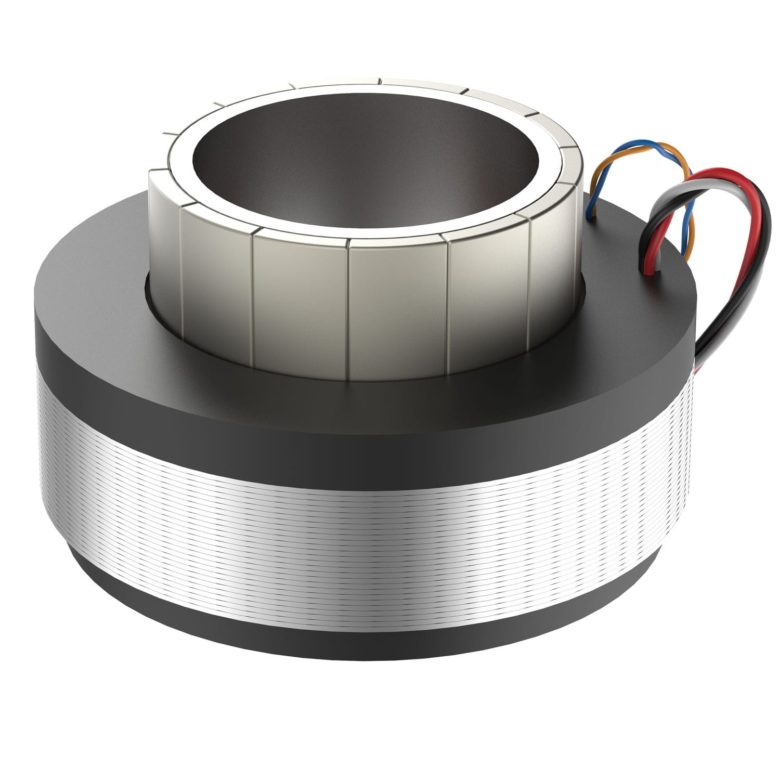

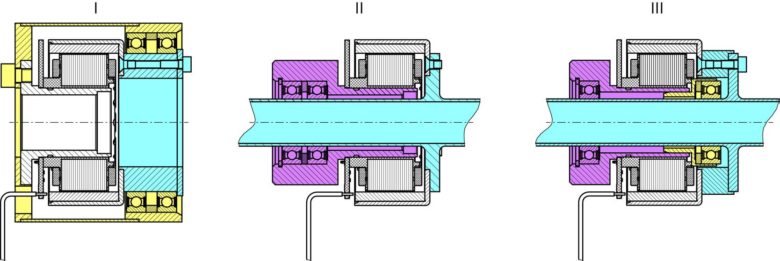

Frameless motors simply said, are simple motor units that are made out of a stator assembly and a rotor assembly. Both are connected through permanent magnets, but frameless motors don’t include shafts, bearings, or any endbells. The science and logic behind frameless motors are that they will be directly integrated into the mechanical structure of the machine. The rotor will be connected directly to the machine and used to rotate the shafts. This, ultimately, leads towards better and more optimized design, reduction in footprint, and making the machine lighter.

What are the advantages of frameless motors?

There are multiple advantages of frameless motors in machine integration. One of the best ones being that they increase rigidity when integrated into a machine. Since there are no mechanical elements, or parts, between the frameless motor and the load, the dynamic performance is drastically increased. Another great advantage is that the motor and load, upon integration, become one inertial mass. In addition to having no mechanical parts between the frameless motor and load, the lifetime of the entire machine is increased and maintenance costs are reduced tenfold. According to Rozum Robotics, frameless motors are best used for those machines and appliances where the mechanical elements are costly to maintain.

How to size a frameless motor

Sizing a frameless motor is not that difficult, and it involves the same steps you would normally take while sizing a housed motor. At the base of it, you would need to calculate the speed and torque based on the load inertia, acceleration, friction, etc. There is a simple formula (Ke/Vkrpm) that calculates the speed requirement of one frameless motor. This formula also calculates the available voltage to the motor to approximate your motors constant voltage requirement. Below we will post an example of how you would calculate the speed and voltage.

If the required speed is 3,000 rpm, and the voltage at 120 VAC, or 168 VDC from the drive, then we will use the formula mentioned above and calculate the approximate Ke. We take the voltage and divide it by the speed (168/3=56 V/Krpm) and we get the final approximate Ke.

For safety reasons, you would add 10% more to the final outcome to factor in voltage drops.

Total voltage requirement is another thing that has to be factored in. If we use the example mentioned above, we can determine the total voltage requirement by calculating IR + BEMF. The required speed remains 3,000 rpm and the voltage remains at 168 VDC. Morot Ke is at 50 V/Krpm (since we factored in that 10 %) and the required torque is at 250 oz-in. Motor torque constant (Kt) is at 60 on-in/amp and the motor resistance at 2 ohms.

So based on that we can use the formula IR + BEMF= (250/60×2) + 50 x 3= 158 volts to meet your total rpm requirements. Your available voltage is at 168, so that makes your calculations correct and viable.

What are frameless motors used for?

Frameless motors work best with machine tools, centrifuges, mixers, winders, or any other applications or tools where mechanical elements represent additional maintenance costs and take much space.