In today’s fast-paced world, where industries are constantly evolving and pushing the boundaries of innovation, one key aspect that cannot be overlooked is the impact on the environment. With increasing concerns about climate change, pollution, and sustainability, it has become imperative for industries to find ways to reduce their ecological footprint. This is where environmental chambers come into play, offering a fascinating solution that combines science and technology to address these challenges.

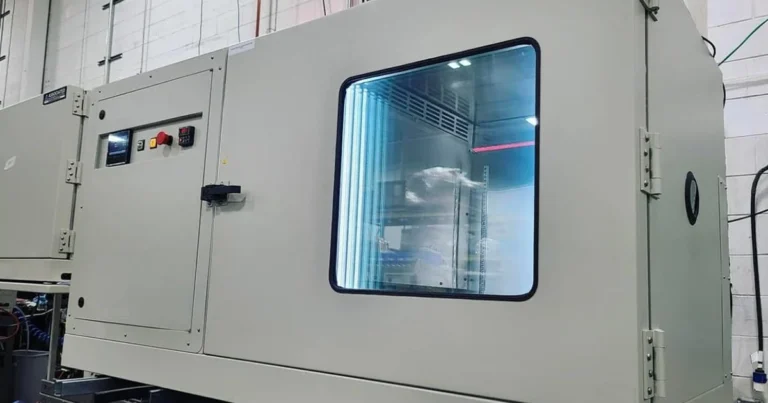

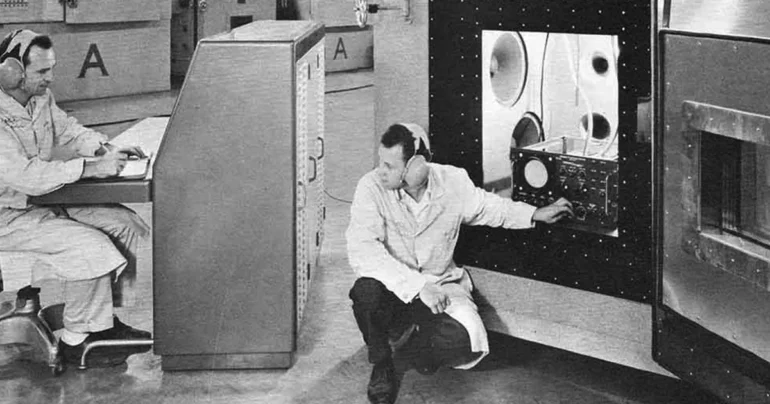

So, what exactly are environmental chambers? In simple terms, they are controlled environments designed to simulate real-world conditions for the purpose of testing and evaluating the effects of various factors on products, materials, or organisms. These chambers provide scientists, researchers, and engineers with the ability to study and understand how different elements, such as temperature, humidity, pressure, and lighting, can influence the performance and durability of a wide range of products.

One of the key reasons why they matter is their role in product development and quality assurance. Whether it’s electronics, pharmaceuticals, automotive parts, or even food and beverages, manufacturers need to ensure that their products can withstand the rigors of the real world. By subjecting them to controlled environments, potential weaknesses and vulnerabilities can be identified and addressed before they reach the market. This not only saves companies from expensive recalls but also contributes to the overall sustainability by minimizing waste and improving product longevity.

Now, let’s dive into the science behind these chambers and explore how they work. At the core of an environmental chamber lies a sophisticated system of sensors, controllers, and actuators that work together to maintain precise environmental conditions. For example, temperature control is achieved using heating and cooling elements, coupled with feedback mechanisms that constantly monitor and adjust the chamber’s internal temperature. Humidity control follows a similar principle, with humidifiers and dehumidifiers working in tandem to maintain the desired moisture level.

In addition to temperature and humidity, they can also simulate other environmental variables. Some chambers are equipped with lighting systems that can replicate natural sunlight or specific spectra to study the effects of light on photosensitive materials or plant growth. Others can create varying air pressure conditions to evaluate the performance of aerospace components or assess the impact of altitude on certain products. These chambers can even mimic specific climatic conditions, such as extreme heat or cold, allowing researchers to understand how different materials behave under such circumstances.

The data collected from these controlled experiments is invaluable for making informed decisions in product development and optimizing performance. For example, in the automotive industry, environmental chambers play a vital role in testing vehicle components for extreme weather conditions. By subjecting parts to high temperatures, freezing temperatures, or even corrosive environments, manufacturers can ensure that their vehicles can withstand the harshest conditions faced by consumers worldwide.

Moreover, they also find significant applications in research areas such as pharmaceuticals, life sciences, and agriculture. They enable scientists to create optimal growth conditions for cells, bacteria, and plants, facilitating experiments that lead to breakthroughs in medical treatments, crop cultivation techniques, and genetic studies. By precisely controlling the environmental factors, researchers can eliminate confounding variables and gain a deeper understanding of how different organisms respond to specific conditions.

In conclusion, environmental chambers are indispensable tools that bridge the gap between laboratory simulations and real-world conditions. As industries continue to prioritize environmental sustainability, the use of environmental chambers will undoubtedly become even more prevalent, enabling us to design products that are resilient, efficient, and environmentally friendly.