Laser marking is something that a lot of people in 2024 need. But, deciding whether to go for Fiber or CO2 laser marking is not the easiest choice to make, and today we’re here to tell you why. These two things are different, and both of them have their special use in certain situations. As a general rule of thumb, for organic materials, it’s better to go for a CO2 device, while for marking metal it’s better that you purchase a fiber one. But, things are not as black and white as most of us would like them to be.

In this 2024 comparison guide, we’ll help you make a better decision by providing concise and trustworthy information. We’ll try to keep things simple and understandable even for those who are complete beginners in the material marking field. So, let’s not keep this introduction longer than it needs to be. Here’s what you need to know.

What are fiber lasers used for?

A lot of people think that fiber lasers are superior when compared to CO2 models, and although there’s a good reason to think that, we still believe that both of these types are equal. Why? Because they have their strengths and weaknesses. But, for you to understand this thoroughly, we must explain both types separately. Let’s take a look.

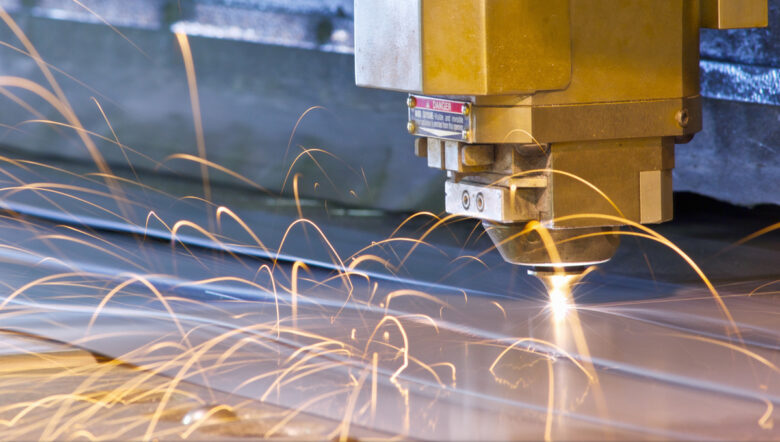

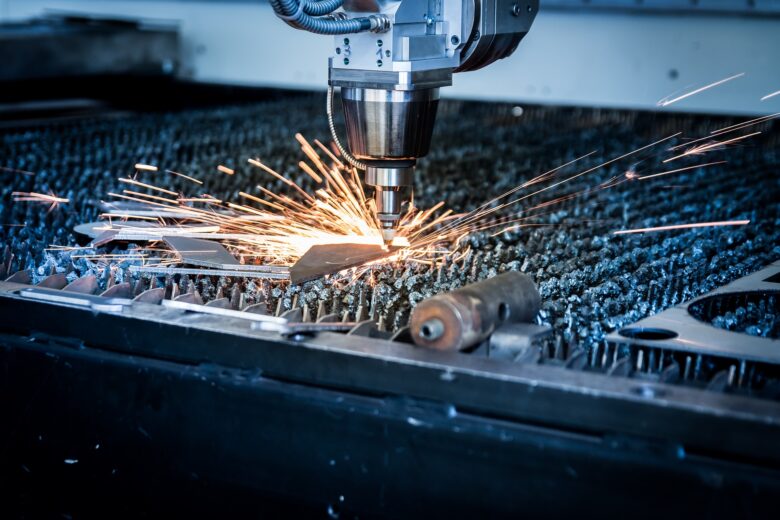

So, fiber lasers are mostly used for something called “high contrast” engraving. What exactly this means is materials such as metal and other hard surfaces that need very precise engravings. This is where fiber lasers excel. Their focal diameter is very small, but the intensity of the heat can be about a hundred times larger, or should we say stronger than CO2 machines. So, simply said, if you need something that’s going to cut very precisely into a sturdy material, you need a fiber laser.

Perks of fiber lasers

If we had to choose one thing that people like the most about fiber lasers, it’s the fact that they are completely maintenance-free. You don’t have to worry about any activities regarding that, but that’s not all. Combine this with the fact these things have more than a hundred thousand operating hours before you’ll ever need to replace them, and you’ll quickly realize why they are the favorite tools for many who engage in activities such as laser marking and engraving.

Last but not least, they are smaller than CO2 machines, meaning that they’ll take less space in your workroom. Also, you can stack many of them in one place due to their compactness. But, although all of this is great about them, it still doesn’t make fiber models superior to CO2. Let’s give the “underdogs” a chance to go.

What are CO2 lasers used for?

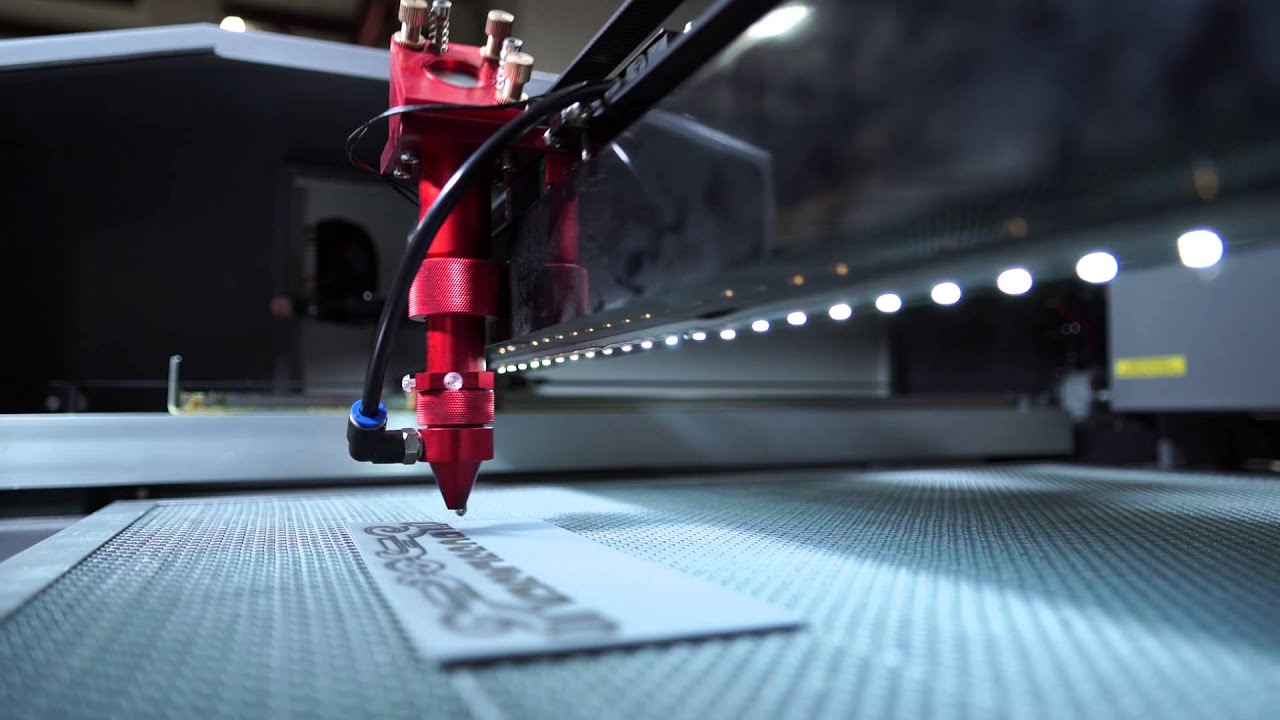

It’s time to introduce the competitor, the CO2 lasers. Now, these things are mostly used for engraving and marking materials that are considered non-metallic, or as some would like to say “organic”. But, this doesn’t mean that CO2 lasers can’t cut thick materials. hispeedlaser.com is a website where you can take a look at a few different co2 lasers marking machines. Use the internet to your advantage when purchasing such products. Pictures and listed features are important so that you know what you’re getting for your money.

You can use them for stones, plastics, wood, and glass even. Everything that is thicker than 5mm can be cut very quickly with the CO2 lasers. But, this has a few disadvantages on its own. Let’s take a look.

Since they are providing a very fast piercing time, they also consume more energy, In fact, significantly more than fiber lasers. If you use multiple of these at the same time, the costs can be quite high, but they are almost always used in large factories where this isn’t such a significant factor.

But, this is not such a significant downside when you consider the fact that CO2 models are quite less expensive than fiber lasers. Fiber models can cost up to a hundred thousand dollars, where top-quality CO2 laser machines are somewhere between thirty-five thousand and sixty thousand dollars.

Perks of CO2 lasers

The perks of these machines are lower prices, higher power, and more diversity. CO2 laser machines can be used on a huge variety of products and materials. Simply said, you have more freedom with them than you do with fiber lasers. For straight-line cutting and smooth surface finishing, they are the better option. As you can see, the difference between these two competitors is not as black and white, and it takes quite a lot of thinking and effort to call someone a winner. But, we have to conclude just for the sake of it. Let’s take a look at that as well.

The final result of our comparison

So, as a conclusion, we learned that fiber lasers cost more money, but they are newer technology and they don’t waste as much energy as CO2 machines. They are mostly used for marking and engraving metallic materials, as well as for a lot of precise work, such as bar codes and annealing, data matrix, and etching.

On the other hand, we have CO2 machines that are less expensive for the initial purchase, but they take up more space and they consume quite a lot of energy. They are also considered older technology. In the long run, they will make you pay more for your energy bills, but that probably evens out with their price which is quite fair.

It’s difficult to say this, but we feel like CO2 machines “win” just for a little bit due to their affordable price, and the fact that they’re still used quite a lot more than fiber lasers in all industries together. But, if you specifically need what those models have to offer, then there’s not much thinking that you should do. Fiber lasers are more expensive but if you plan to use them for many years you’ll save some money due to their lower costs thanks to new and improved technology.