In today’s industrial landscape, automation plays a pivotal role in maximizing productivity and efficiency. One of the key components driving this automation revolution is the Programmable Logic Controller (PLC). PLC controllers are at the heart of industrial machines, enabling precise control and monitoring of various processes. This article explores the significance of PLC controllers in industrial automation and highlights their key features and applications.

Specialized Digital Computers

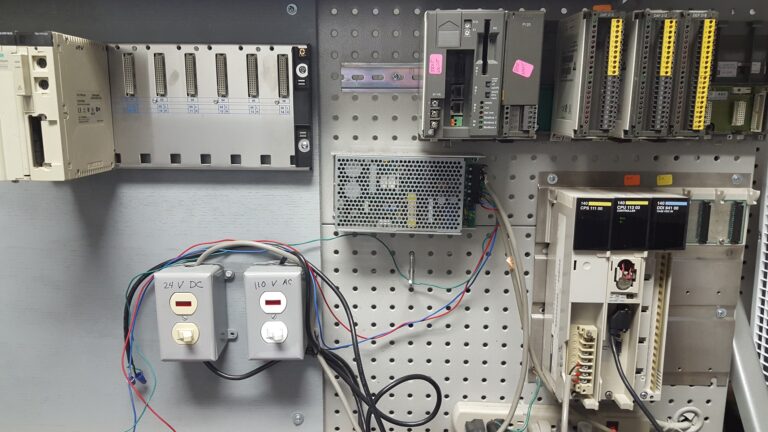

PLC controllers are specialized digital computers designed to automate electromechanical processes in manufacturing environments. These versatile devices receive input signals from sensors, switches, and other control devices, and based on pre-programmed logic, they execute specific actions through output modules such as motor starters, solenoids, and actuators. This capability allows PLC controllers to coordinate and control complex operations within industrial machinery.

Advantages of PLC Controllers

One of the primary advantages of PLC controllers is their flexibility. Unlike traditional relay-based control systems, PLCs can be easily reprogrammed to accommodate changes in manufacturing processes or production requirements. This flexibility reduces downtime and increases the overall efficiency of industrial operations. Furthermore, PLCs offer modularity, enabling easy integration with other automation components such as Human-Machine Interfaces (HMIs), Supervisory Control and Data Acquisition (SCADA) systems, and Distributed Control Systems (DCS).

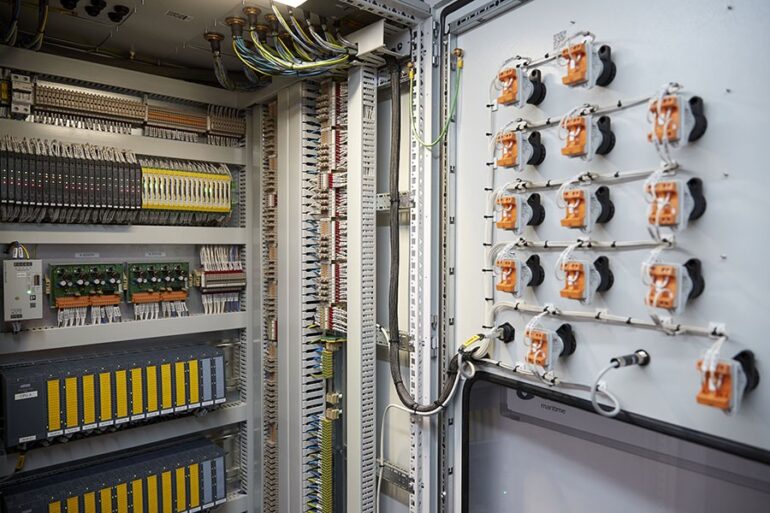

PLC controllers provide a wide range of features that enhance industrial automation. Firstly, they offer robust and reliable operation in harsh industrial environments. PLCs are built to withstand temperature variations, electrical noise, and vibration, making them suitable for deployment in rugged conditions. Additionally, these controllers have extensive input/output (I/O) capabilities, allowing seamless connectivity to a plethora of sensors, switches, and actuators. This versatility enables precise monitoring and control of parameters such as temperature, pressure, flow rate, and motor speed.

Moreover, PLC controllers are equipped with advanced programming languages, such as ladder logic, function block diagrams, and structured text, to facilitate the development of complex control strategies. These programming languages offer a graphical representation of the control logic, making it easier for engineers and technicians to design, modify, and troubleshoot industrial automation systems. Additionally, PLCs support data logging and communication protocols, enabling seamless integration with enterprise-level systems for data analysis, remote monitoring, and predictive maintenance.

PLC controllers find applications across various industries. In the manufacturing sector, PLCs are extensively used for controlling assembly lines, robotic systems, and material handling equipment. They enable precise synchronization of multiple processes, ensuring smooth operations and reducing the likelihood of errors. PLCs are also employed in the energy sector to monitor and control power distribution systems, generators, and renewable energy sources. In the automotive industry, PLC controllers manage complex operations within production lines, ensuring efficient manufacturing and high-quality outputs.

Furthermore, PLC controllers are crucial for process automation in sectors such as oil and gas, pharmaceuticals, food and beverage, and water treatment. They enable precise regulation of parameters like temperature, pressure, and flow rate, ensuring consistent product quality and adherence to safety standards. PLCs also play a vital role in building automation, controlling HVAC systems, lighting, and security devices, thereby enhancing energy efficiency and occupant comfort.

In recent years, there has been a surge in the demand for MRO Electric services related to PLC controllers. MRO Electric specializes in providing repair and replacement services for a wide range of industrial electronic equipment, including PLC controllers. Their expertise ensures minimal downtime and efficient resolution of technical issues, helping businesses maintain smooth operations and productivity. With their comprehensive knowledge and experience, MRO Electric supports industries in optimizing the performance of PLC controllers and associated automation systems.

The significance of PLC controllers in industrial automation cannot be overstated. These controllers have proven to be indispensable components that enable precise control, monitoring, and coordination of various processes in manufacturing environments. The flexibility, reliability, and extensive feature set of PLC controllers makes them well-suited for a wide range of applications across diverse industries.

One of the key advantages of PLC controllers is their flexibility. Unlike traditional control systems, PLCs can be easily reprogrammed to adapt to changes in manufacturing processes or production requirements. This flexibility reduces downtime and allows for efficient modifications, ensuring that industrial operations can quickly respond to evolving demands. PLCs also offer modularity, allowing for seamless integration with other automation components such as HMIs, SCADA systems, and DCS. This integration enhances the overall efficiency and effectiveness of industrial automation systems.

The reliability of PLC controllers is another crucial aspect that contributes to their widespread adoption. These controllers are designed to operate in harsh industrial environments, where they can withstand temperature variations, electrical noise, and vibration. This ruggedness ensures that PLCs can consistently perform in demanding conditions without compromising their functionality. By providing robust operation, PLC controllers minimize the risk of system failures and maximize the uptime of industrial machinery, resulting in increased productivity and reduced maintenance costs.

Furthermore, the extensive feature set of PLC controllers enhances their versatility and applicability in various industries. PLCs offer a wide range of I/O capabilities, enabling seamless connectivity to sensors, switches, and actuators. This connectivity allows for precise monitoring and control of critical parameters such as temperature, pressure, flow rate, and motor speed. With advanced programming languages such as ladder logic, function block diagrams, and structured text, engineers and technicians can develop complex control strategies with ease. The graphical representation of control logic offered by these programming languages simplifies system design, modification, and troubleshooting.

In addition, PLC controllers support data logging and communication protocols, facilitating integration with enterprise-level systems for data analysis, remote monitoring, and predictive maintenance. The ability to collect and analyze data from PLC controllers provides valuable insights into industrial processes, enabling businesses to optimize performance, identify inefficiencies, and make informed decisions. PLCs also play a crucial role in ensuring compliance with safety standards and regulatory requirements, particularly in sectors such as oil and gas, pharmaceuticals, and food and beverage, where precise control and adherence to guidelines are paramount.

PLC Continues to Expand

As technology continues to advance, the role of PLC controllers in industrial automation will continue to expand. Industries across the globe are increasingly embracing automation to improve productivity, efficiency, and innovation. PLC controllers, with their proven track record and adaptability, will be at the forefront of this automation revolution. Additionally, companies like MRO Electric, specializing in electric services for PLC controllers and other industrial electronic equipment, will play a vital role in supporting businesses in maintaining smooth operations and optimizing the performance of their automation systems.

Conclusion

In conclusion, PLC controllers have revolutionized industrial automation by providing precise control, monitoring, and coordination of processes. Their flexibility, reliability, and extensive feature set make them essential components across diverse industries. As technology advances and industries embrace automation, PLC controllers, along with supporting services from companies like MRO Electric, will continue to drive productivity, efficiency, and innovation in the industrial landscape. By leveraging the capabilities of PLC controllers, businesses can achieve higher levels of operational excellence and stay competitive in an increasingly automated world.